Today’s brass case factories operate on the principles of traditional mass production techniques, developed in the early 1900’s. In an effort to maximize efficiencies, machines are grouped in common departments, turned up to run as fast as possible and large inventories are used to buffer inconsistencies. Machines are difficult to set up and adjust. Specialized technicians are required to make changeovers, sometimes taking several days. High inventory levels drive slow process speed, with as much as 4 Months inventory from beginning to end. It’s impossible to stop production if a defect is discovered; it’s easier to add 100% inspection at the end of the process. Lastly, today’s ammunition plants are loud and earplugs are required everywhere on the shop floor. It’s impossible to have an understandable conversation.

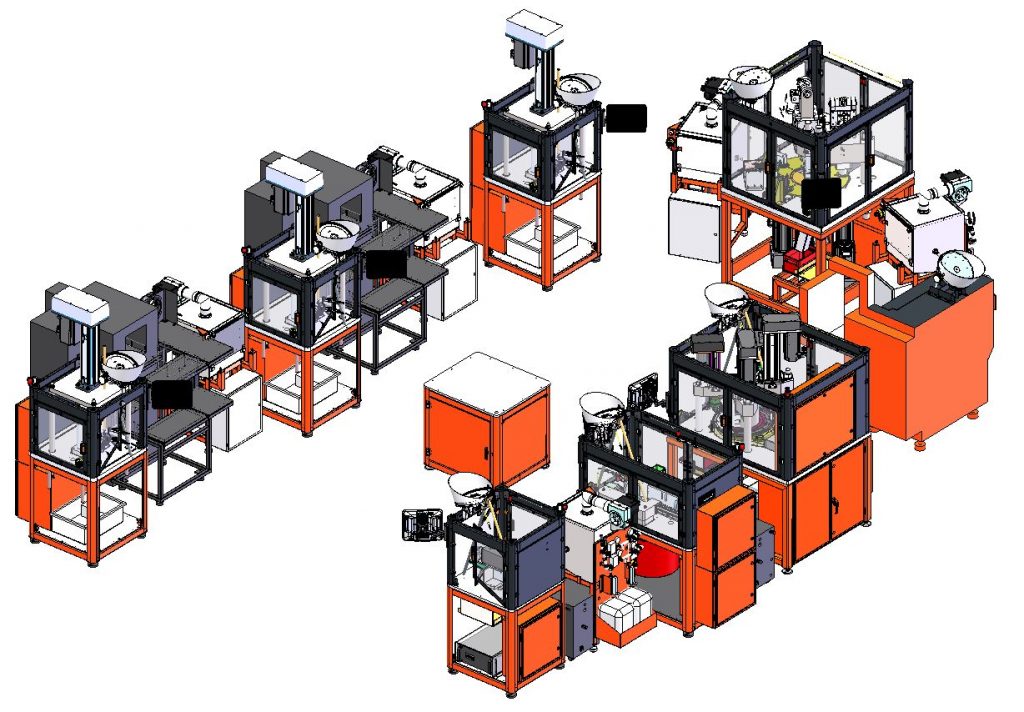

Setpoint has designed a brass case U shaped cell (shown below) that positions the operator on the inside and available to service all machines. All tooling and equipment needed to produce a brass case, from first draw to final anneal, are positioned around the U.

Starting with first draw, brass cases are sequentially processed through each machine until the case is completed. It is designed to hold 15-30 minute buffers between each machine and takes approximately 4 hours to complete a case from beginning to end. Including 4 anneal and 5 individual wash operations.

Quality is monitored using statistical process control (SPC) sampling plans at an inspection table in the middle of the cell. Adjustments are a snap with servo linear actuators. When a machine requires an adjustment – the operator simply enters an offset on the touch screen and the dimension is adjusted without stopping the machine. Capabilities of 6 sigma or better are common with this servo actuated technology.

Each machine is designed with versatility in mind. The cell offers optional calibers between .223 through .338 Lapua. Quick-change concepts have been incorporated, similar to the early days of Toyota. Each machine is capable of 30 minute or less changeover from one caliber to another.

An intriguing aspect for the cell is lack of loud noise, having employees engaged in the continuous improvement process is mandatory in any lean organization. Conversations are possible inside the cell without yelling through earplugs.

Labor content is low. The inside operator tends all machines and conducts SPC inspections. An outside operator monitors hardness testing, chemistries and minor machine maintenance. Status lights (Andon) are on each machine providing quick operator feedback when machines need attention. It’s also important to note that overhead support for the cell is significantly less than traditional manufacturing layouts. This is because a connecting process using a cell requires less production control, less process/quality engineering and less production supervision.

As with the auto industry in the 1980’s, it’s time for a lean revolution in the brass case ammunition world. Improved quality, low inventories, agile/versatile capacity, lower operating costs, lower overhead costs, clean processes and a quiet production environment are a few of the benefits. Join the revolution, call Setpoint Systems at (866) 532-6856, or check us out online at www.setpointusa.com.

I am interested in you manufacturing system, I would like to learn more about it, including line product capacity and cost of complete line,

Thanks,

I have some investors looking at the ammo business as a potential start up business.

Please contact me to discuss.

Thanks!

J.R.

Thanks for your interest. One of our sales consultants will contact you

Hi, i have the same question. I’d like to start up a small ammo business and would like some ideas on what equipment you suggest with associated pricing.

Not sure if request was sent.

Hi – Do you have further information re – setup cost, skill set requirements, cost of goods produced, cost of dies etc.

I would like to establish the return on investment before I assign resources to develop a comprehensive Project Plan.

Regards

Kim.

Would like information on a complete system. How large of foot print does the system require. What would the cost of a entire system cost. Does the System require you to set up.

Good Morning

I am living in South Africa and would like to acquire one of your production lines I do have a few questions:

1. What are the costs for the entire production line?

2. What kind of training is required to run this machinery and do you offer any training?

3. How much floor space is required to house the entire production line?

4. What kind of back up service and warranty is offered with the machinery?

5. At full production how many cases can the line turnout per hour?

Kind Regards

Dean

Dear Sir,

We are one of Special equipment supplier to our Defense sector Ammunition Industry in India, We need to built two complete line for Manufacturing of Cartridge cases, If you are interested we would like to Get your supports by Machines and technical to Build complete setup, kindly provide the further information how to contact

Thanks and regards

P. Jayachandra Mohan

Proprietor

P. Chandru Machine Tools

Vellore, Tamilnadu, India

I am looking to start a small arms ammunition plant and I am interested in your loading machine. What is the price of a base model loader and would I be able to run production in .22 calibur

Thank you, Jeromy

Unfortunately at this time we do not offer machines to manufacture rimfire cases or ammunition. If you would like more information about manufacturing centerfire cartridges, you can send us an email at [email protected]

Good morning,

I’m making finance marketing to choose equipment for producing .223,.308, .40s&w, .9×19 Luger cartridges.

Is it possible to have some pricing information about your line?

What is capability of your line (shown in video)?

Are you wanting to know about case manufacturing or priming and loading?

The whole process including case and bullets manufacturing priming and loading.

I am interested in gathering some more information on bullet manufacturing and will need information from your sales dept. Please.

As a scope for your feed back could you correlate what it would take to deliver 5k 308 cal. a day in production?

Regards,

LB

I will have a salesperson get in touch with you with more information

please contact us by phone or by our email concerning your complete brass cartridge Manufacturing line

i am interested in manufacturing system i would like to know cost of complete production line

Do you offer any rimfire applications? Thx, John

We do not offer any machinery for rimfire at this time

Please let me know where I can get more information.

Thank you.

Joe R.

Tulsa, OK

Someone from our sales team will contact you through the email you used to comment

Dear MrMrs

I’m a representative of Ukrainian company Tanacov’s Co (Company KARE in other words). We are cooperating with many companies in Arab Emirates, China + Hong Kong, Bulgary for long time and have many different specifications in our work.

We want to start a production of mettalic and rubber cartridges (non war) cartridge cases for non war guns, production of rubber bullets etc. These production will be contain production of cartridges, stuffing them by gunpowder, inserting of bullet and capsule, rolling of a sleeve. These may be done by programm machines or by electrical mechanical machine with a help of peaple. They may be new or already used but good working.

Firstofall we are interested in the production machine for the gun 9mm8mm (different sizes 7.62*54mmR, 7.62*39mm, 9*18mm for rifle, for a gun, revolver, ) and the equipment for cartridge, bullet, and shell production the same sizes.

Would You be so kind to propose us all You have for such production (from start till the end) with pictures and prices (maybe videos). Tell us You terms and conditions of order, delivery that can help us to make an order as soon as possible.

Maybe You have representatives in our country?

Thank You very much in advance

Hope for long term relationships in our work

With best regards

Julia Black

[email protected]

+380979232604

Can the process be started with brass strip material? (I saw your video starts with copper cup) Please contact us – Master Arms LTD in Bulgaria is Ammo Manufacturer (assembly plant). We are looking into ways to make our own brass casings.

Hi Nikola

Our machines must start with a brass cup. Let me know if I can help with anything else.

Josh Hays

Dear sirs/

About your enterprise I knew information from the Ukrainian magazine “Weapon and Hunt”. With told the informative article, that Your enterprise had been the supplier of equipment for a firm Nexus. As you know in Ukraine now difficult situation and our country must organize a few factories on the production of cartridges. A situation is difficult that the issue of not only cartridges on the standards of NATO (308 and 338) but also cartridges is needed on the standards of the USSR.Naturally, for such aims an equipment is needed with simple and rapid setting and adjusting. On the basis of preliminary to the studied information, Your equipment well befits for these aims. Our suggestion about a collaboration with you following: We want to become Your official representatives in Ukraine for the sales of equipment private and state enterprises. In addition, we want officially to carry out also the sales of spare parts, riggings for presses, service services. I ask to consider our suggestion. Possibly you will offer the forms for a collaboration. Ready to answer any Your questions. With kind regards.

Dear Sir,

Would you please send me details of bullet casing manufacturing facilities ? I am a metallurgist myself with a strong tube manufacturing background. Currently, I am assigned to have a feasibility study to produce bullet casing.

Details of plant lay out, drawing machines, annealing furnace and final machining would be appreciated including the cost of each machine to get a total cost of the facilities.

We could have further discussion by direct contact.

Kind regards,

Kukuh Wanengkirtyo

I am interested in machinery to produce 22lr. I would like to know the cost. Thanks.