Industrial Automation

Setpoint has been delivering industrial automation equipment for manufacturers for 25 years. During this time period, Setpoint has successfully designed and built automated equipment for thousands of custom automation applications for a large number of businesses in a wide variety of industries. Setpoint can provide a full in-house range of automation services that will help you achieve your manufacturing goals, including:

- Process Development

- Machine Design

- Machine Controls

- Fabrication and Assembly

Setpoint Industrial Equipment Technology

Setpoint’s expertise in many different technologies has enabled us to develop cost-saving solutions for a variety of manufacturers. Some solutions include:

- Fully Automated Systems

- Equipment Upgrades and Re-Tooling

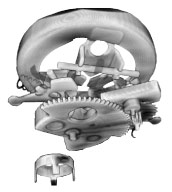

- Ammunition Manufacturing Equipment

- Custom Automated Solutions

- Testing & Inspection Equipment

- Energetic & Explosive Devices Automation

- Robotic System Integration

Improve Quality

Improving the quality of your products and processes is a key reason to consider automation. Through industrial automation in your manufacturing process you can gain precision that is not possible with manual human operators.

Another key area for improving quality is the testing process. Through non destructive testing procedures you can reduce costly future repairs and defects by ensuring flaws are found and fixed early. You can setup your factory to randomly spot check specific areas of concern or have a complete 100% automated system to inspect all parts. There are many other types of non destructive testing to consider from x-ray inspections to electrical testing and everything in between.

Achieve Flexibility

Lean automation is one key component of a flexible manufacturing process. Having compact units that can easily be re-tooled within a short period of time is critical. Having a lean production line will allow you to produce multiple units from many different variable parts. Parts can vary in size, color, orientation, etc.

If you have very unique needs and specifications a custom automated solution can be developed to meet your demands. Some manufacturers are most concerned with quality, others with cost, and some with flexibility or productivity. Having a custom system will ensure that it is built with your key concerns satisfied.

Increase Productivity

Improving the quality of your output in your factory or manufacturing facility is a key reason to consider automation. Through integrated automation you can gain productivity levels that are not possible with human operators.

One example of a successful custom automated solution is Setpoint’s real time radiography x-ray inspection machine. We combined two machine’s processes into one machine, reduced required factory floor space by 75%, and decreased the labor minutes used per unit by 50%.

Reduce Costs

Reducing overall manufacturing costs is a positive side-effect of all of the above mentioned topics. Although upfront fees can be slightly higher, in the long-term industrial automation processes can significantly reduce costs through higher quality, less defective parts, flexibility in the manufacturing line, and increased productivity.

Manufacturing Safety

Having a safe manufacturing environment is of great concern to anyone in the industrial world. We will take necessary steps to ensure all automated solutions, robot integration, and custom machines will be safe to use. Another manufacturing area of major concern with safety is explosives and energetics automation. If you handle explosives or energetic materials we can assist you in developing a custom solution for weighing, filling, and assembly of parts while keeping staff safe. Rest assured that no matter what industrial automation solution you are looking for it will consist of the highest quality and safety.

Improve Quality

Improving the quality of your products and processes is a key reason to consider automation. Through industrial automation in your manufacturing process you can gain precision that is not possible with manual human operators.

Another key area for improving quality is the testing process. Through non destructive testing procedures you can reduce costly future repairs and defects by ensuring flaws are found and fixed early. You can setup your factory to randomly spot check specific areas of concern or have a complete 100% automated system to inspect all parts. There are many other types of non destructive testing to consider from x-ray inspections to electrical testing and everything in between.

Achieve Flexibility

Lean automation is one key component of a flexible manufacturing process. Having compact units that can easily be re-tooled within a short period of time is critical. Having a lean production line will allow you to produce multiple units from many different variable parts. Parts can vary in size, color, orientation, etc.

If you have very unique needs and specifications a custom automated solution can be developed to meet your demands. Some manufacturers are most concerned with quality, others with cost, and some with flexibility or productivity. Having a custom system will ensure that it is built with your key concerns satisfied.

Increase Productivity

Improving the quality of your output in your factory or manufacturing facility is a key reason to consider automation. Through integrated automation you can gain productivity levels that are not possible with human operators.

One example of a successful custom automated solution is Setpoint’s real time radiography x-ray inspection machine. We combined two machine’s processes into one machine, reduced required factory floor space by 75%, and decreased the labor minutes used per unit by 50%.