Custom Automation Solutions

Setpoint Systems is a full service lean automation engineering company that specializes in design, build, and controls programming of turn-key custom automation solutions designed to precisely meet each customer’s specifications and needs. We are the leader in custom automation equipment for manufacturing companies who need to assemble, test, or inspect their products. We have helped manufacturers large and small improve the way they make and distribute goods. They spend less to produce more, and end up leading their industries in innovation, profit and growth.

Custom Automation Experience

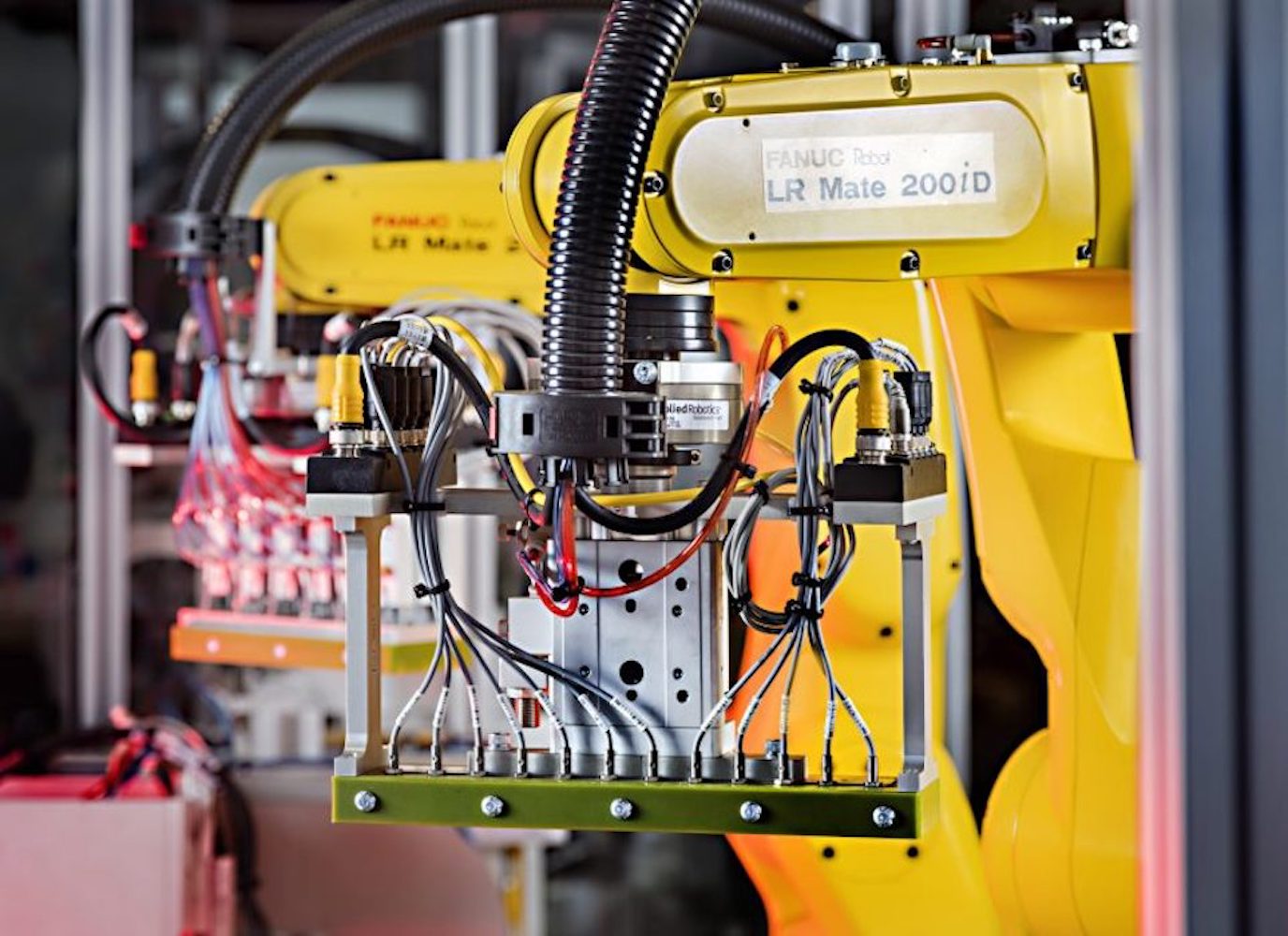

- Robotics

- Assembly Equipment

- Material Handling

- Test & Inspect

- Induction heating

Industry Experience

- Automotive

- Aerospace

- Ammunition

- Medical devices

- Packaging

- Clean energy storage

- Amusement

Let’s talk about your next automation project

EV Battery Assembly

Setpoint has helped the world’s leading EV manufacturers design and build lithium-ion cell handling equipment with designs ranging from single-cell to multi-cell part handling. Our equipment will perform an electrical check and load the battery cells per the customer’s needs. Additional applications include lot mixing, cell flipping, barcode reading, part tracking have been incorporated without sacrificing required rates. Regardless of the customer’s unique battery needs, Setpoint can help test and load to exactly meet their needs.

- Collector Plate Assembly Cells

- Cell Test Load Cells

- Ultraviolet Potting Cells

- End of Line Battery Assembly

- Curing Material Handling Cell

- Battery Enclosure Assembly Cells

Lean Automation

Setpoint builds automated manufacturing equipment suited for lean manufacturing systems and traditional processing techniques. Each automated solution is lean and upholds the lean manufacturing tenets of:

- Right sized machines that are conducive to flow

- Highly reliable and self-diagnostic equipment

- Modular standard equipment which facilitates future adaptation for new product families

- Smart tooling that poka-yokes (error proofs) and accommodates on-the-fly model changeover

- The Toyota Production System provides lean guidelines that can be applied to many industries

Automated Assembly Equipment

Setpoint’s automated assembly equipment experience ranges from battery testing and loading to assembling devices using explosive powder to torque assembly machines that tighten screws to a specific spec for final positioning on a part. Assembly experience ranges from small 2-3 component assemblies to larger scale assemblies requiring 40 simultaneous operations.

Test and Inspection Systems

Ensuring that each of our client’s many products meet strict quality metrics is something Setpoint understands and makes possible. Our custom automation systems include fully automated, high throughput testing and inspection machines that are designed to provide 100% testing for the parts on the line.

Custom Automation Benefit: Productivity

Custom automation equipment can increase your productivity, check for bad parts, and reduce your scrap rate.

Custom Automation Benefit: Quality

Custom automation equipment can gain precision in manufacturing processes. Spot check or 100% inspect all parts.

Custom Automation Benefit: Reduce Waste

Custom automation can save you money as you reduce your scrap/defective parts and increase your productivity.

Custom Automation Benefit: ROI

Custom automation equipment solves problems; decrease waste, cycle time, rework, and labor minutes per unit. Get a return on better parts.

Custom Automation Benefit: Time

Custom automation will save time with better uptime and operational availability (OA)

Custom Automation Benefit: Safety

Custom automation equipment can provide a safe manufacturing environment. Safety features keep operators and parts safe.

Why custom automation from Setpoint?

For 25 years Setpoint has helped businesses large and small improve the way they make and distribute goods. They spend less to produce more, and end up leading their industries in innovation, profit and growth.

Custom Automated Equipment Built for Your Needs

Let’s talk about automating your assembly, test, or inspection process.