Lean Manufacturing

Incorporating lean automation functionality is the standard practice on projects by Setpoint.

Our engineers design machines knowing there will be defective parts that need to be rejected prior to the next test, inspection or assembly process. Before parts are ever introduced into the process they can be checked for the right color, orientation, and size. If they don’t pass they are not allowed onto the machine. If during the process a part is found to be defective, the WIP (Work in Process) software will track the specific part and ensure the bad part is confined to a non-compliant materials box.

Setpoint produces turn-key solutions providing right-sized machines that fit into existing production areas. Quick change Single Minute Exchange of Dies (SMED) tooling is used to ensure each system can reach your economic order quantity.

Through electrical and mechanical practices, Setpoint mistake proofs (poka-yokes) each process to ensure correct tooling is installed the right way so that parts are processed correctly. An essential part of this process rejects bad parts from being passed through to the next assembly.

Lean Systems

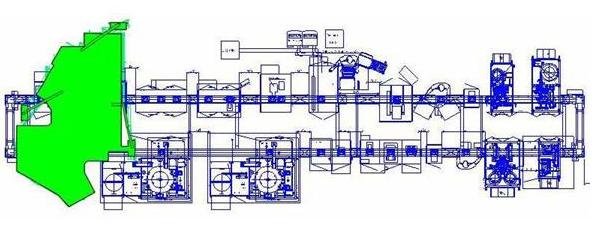

Footprint is an essential element of lean, keeping the machines compact, simple and easy to work on is critical in the manufacturing process. Setpoint has designed work cells for production lines that have individual stations for each step in the process that can be re-tooled to incorporate a change in the part or process. Setpoint has also designed machines that perform multiple processes all within the same footprint.

This image is an overlay between a production line using linear technology in blue and the Setpoint line using lean automation in green. The lean system provided by Setpoint reduced the footprint by 83% from the original system.

Toyota Production System

Toyota Production System Philosophy

The main philosophies, cultural values and overall process of the Toyota Production System (TPS) are what have driven its worldwide notoriety. Following are some of the main philosophies of the Toyota Production System that make it so universally successful, regardless of what industry you are in.

- Having a long-term philosophy that drives a long-term approach to building a learning organization

- Base your management decisions on a long-term philosophy, even at the expense of shorter financial goals

- The right process will produce the right result

- Create a continuous process flow to bring problems to the surface. Use constraint management to tackle the biggest to smallest issues in order of impact.

- Use the “pull” systems to avoid overproduction. This will help uncover issues in your manufacturing process, rather than masking it with piles of overproduced product at each station.

- Level out the workload (heijunka). Build orders as they come in. Don’t batch and queue your production.

- Build a culture of stopping to fix problems, to get quality right the first time. Empower everyone to stop production of non-compliant material (NCM) parts.

- Standardized tasks and processes are the foundation for continuous improvement and employee empowerment. Standardization breeds efficiency at all levels of the operations.

- Use visual control so no problems are hidden. Visual indicators can create a fast and easy way to take the pulse of the operation at all levels without requesting time consuming charts and data sheets to be compiled.

- Use only reliable, thoroughly tested technology that serves your people and processes

- Add value to the organization by developing its people and partners

- Grow leaders who thoroughly understand the work, live the philosophy, and teach it to others

- Develop exceptional people and teams who follow your company’s philosophy

- Respect your extended network of partners and suppliers by challenging them and helping them improve.

- Continuously solving root problems to drive organizational learning

- Go and see for yourself to thoroughly understand the situation. Manage by walking around your operations rather than sitting in your office and expecting things to change.

- Make decisions slowly by consensus, thoroughly considering all options; implement decisions rapidly. Once you have proven that changes need to happen, execute as quickly as possible so you can take full advantage of the benefits of your decision.

- Becoming a learning organization through relentless reflection of lessons learned and continuous improvement (Kaizen).

Reduction of Waste

Reducing Waste in all aspects of your operations is key to maintaining the edge needed to compete in the global economy. The Toyota Production System teaches that waste, “muda”, is one of the evils that should be avoided. Following are some examples of ways to reduce waste.

- Reduce Setup Times – All setup practices are wasteful because they add no value and they tie up labor and equipment. By organizing procedures, using carts, and training workers to do their own setups, Toyota managed to slash setup times from months to hours and sometimes even minutes.

- Small-Lot Production – Producing things in large batches results in huge setup costs, high capital cost of high-speed dedicated machinery, larger inventories, extended lead times, and larger defect costs. Because Toyota has found the way to make setups short and inexpensive, it became possible for them to economically produce a variety of things in small quantities.

- Employee Involvement and Empowerment – Toyota organized their workers by forming teams and gave them the responsibility and training to do many specialized tasks. Teams are also given responsibility for housekeeping and minor equipment repair. Each team has a leader who also works as one of them on the line.

- Quality at the Source – To eliminate product defects, they must be discovered and corrected as soon as possible. Since workers are in the best position to discover a defect and to immediately fix it, they are assigned this responsibility. If a defect cannot be readily fixed, any worker can halt the entire line by pulling a cord (called Jidoka).

- Equipment Maintenance – Toyota operators are assigned primary responsibility for basic maintenance since they are in the best position to detect signs of malfunctions. Maintenance specialists diagnose and fix only complex problems, improve the performance of equipment, and train workers in maintenance.

- Pull Production – To reduce inventory holding costs and lead times, Toyota developed the pull production method wherein the quantity of work performed at each stage of the process is dictated solely by demand for materials from the immediate next stage. The Kanban scheme coordinates the flow of small containers of materials between stages. This is where the term Just-in-Time (JIT) originated.

- Supplier Involvement – Toyota treats its suppliers as partners, as integral elements of Toyota Production System (TPS). Suppliers are trained in ways to reduce setup times, inventories, defects, machine breakdowns etc., and take responsibility to deliver their best possible parts.